How to Take Great Photos for Your Farm or Food Brand with Your Phone

June 27, 2023

How to Take Great Photos for Your Farm or Food Brand with Your Phone

June 27, 2023October 15, 2015

A Small Business Guide to Shipping Perishable Food

By Noah Munro, Co-CEO

Large companies like Omaha Steaks can make shipping perishable products look easy, but as a small food producer, selling perishable food online – especially frozen or refrigerated food – can feel a bit more daunting. To help get you started shipping your perishable products, here is some practical guidance along with resources to make it easier to ship food that must stay cold. We’ll explore special packaging, cooling methods, shipping speeds, costs, and more.

Part 1: Design a “Packaging System” to Keep Your Food Cold

Keep the Heat Out: Choose the Right Insulation

There are more options than you might think to protect your temperature sensitive food from the heat of the environment. Here are a few options to consider.

- Styrofoam Boxes: Come in standard sizes, and typically include an exterior cardboard box. They come in various thicknesses. The thicker the wall, the less dry ice or ice packs you’ll need, but the more expensive the box. Request samples from suppliers to test different sizes and thicknesses with your product.

- Styrofoam Cut Sheets: Also come in standard sizes or can be customized to fit any box. These can be a less expensive than the whole box, but may not be as effective at keeping your products cold.

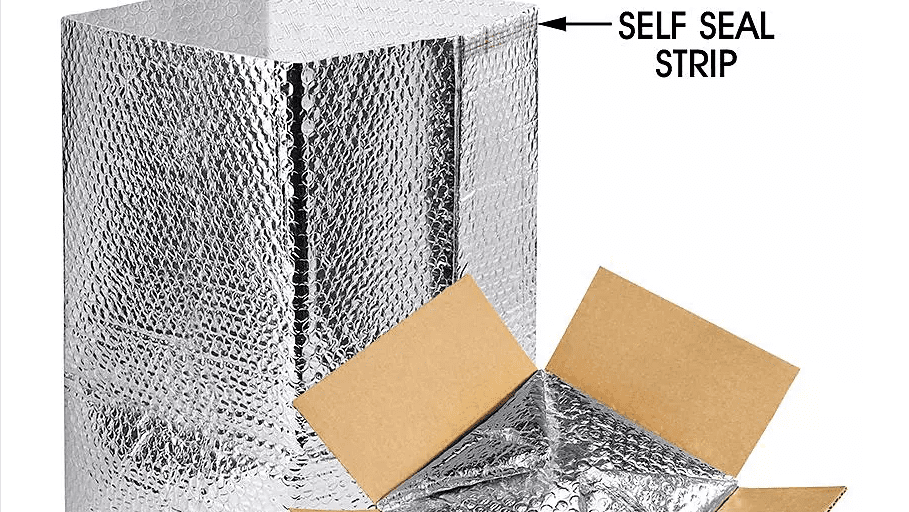

- Insulated Liners: These look similar to emergency blankets, but with a bubble wrap “texture.” The biggest benefit with this option is that you can tightly wrap your product and then fill any extra space in your box with bubble wrap or other packaging.

- Air filled Insulation Liners: These come with a hand pump (for small volumes) and an air tank (for larger volumes) and uses the powerful thermal properties of air, which of course is free, making this option often more affordable.

- Insulated Pads: These combine the insulation effectiveness of Styrofoam with the reflectiveness of the insulated liners, all while providing a “greener” solution as these are made of recycled materials. This solution comes with a fitting cardboard box, or you can order your own boxes from various online suppliers.

Keep it Cold: Dry Ice vs. Ice Packs

The general rule of thumb is to use ice packs when shipping refrigerated items, and dry ice when you need to keep your product frozen.

- Ice Packs: Make sure to test the number and size your product needs INSIDE whichever insulation-providing container you choose. Keep in mind there are also different kinds available, but to save money, you’ll probably only need the one-time use ice packs.

- Dry Ice: You will be handling a hazardous material, which means you’ll have a few extra considerations when labeling your package, and choosing your shipping partner. When using UPS, if you can stay under 5.5 lbs. of dry ice, you’ll avoid extra requirements when shipping by air. No matter how much you use, you’ll need to label the outside of the box showing that it contains Dry Ice. Read more from UPS about shipping with Dry Ice. For Fedex, review their service guide here.

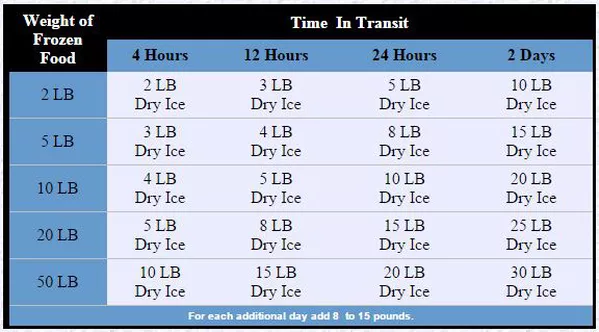

- How much Dry Ice Will I Need?

That depends on how much your product weighs and how long it needs to keep your product frozen. Also consider the temperature of your product when shipped, and account for the season and geographic destination as well. Here’s a helpful chart, courtesy of Dry Ice Info.

Part 2: Choose the Right Shipping Partner

Who Should Deliver Your Food Product to Your Customers?

For products that require guaranteed delivery in 1-2 days, we suggest contacting both UPS and Fedex to find out what types of “incentive pricing” you’re able to get based on your current and projected volume. With UPS, you should be able to negotiate for at least 30% off retail prices without huge volumes. Never build your shipping cost and price model based on full retail prices.

It’s worth the investment of time to research which shipping partner provides the best service for your unique business and products.

Shipping Speed: How many days will your product keep?

You may think you have to overnight your product to be safe, but remember that 2-day shipping is significantly less expensive and may be fast enough. Saving customers money on shipping means they’ll order more often.

The shipping speed required will depend on shelf life and whether you need to keep your product refrigerated or frozen. The key question to ask is: What is the slowest I can ship my product while still ensuring its safe arrival?

With UPS, you can ship within a large regional area via UPS Ground in 1 day or 2 days, which will cost a LOT less than 1 or 2 day air delivery. Just keep in mind that with Ground mail they won’t provide a service guarantee, but our experience at The Mill Fudge Factory has shown UPS Ground to be very reliable.

You might also consider only making shipping available to certain states, at least initially, as you build your volume. If you do however, just be sure to focus your online marketing on your target customers in this region. Also, make sure your shipping policy is readily available on your online food store to avoid any disappointment.

Be a savvy business owner.

Get tips on accounting, finance, marketing, and more, tailored for farms and food businesses—free.

"*" indicates required fields

Intro to Cold Shipping Guide

Part 3: Set Pricing and Manage Costs to Maximize Profits

To save money on your total shipping costs, there are a few considerations:

How Small Can You Go?

Design your packaging system to be as compact as possible. UPS and the USPS set prices based on “dimensional weight” which means they don’t care as much about the actual weight of your package, but instead rely on the dimensions to determine the weight it “should” be. This means that reducing your box by only an inch or two might reduce your shipping cost significantly.

Will Anyone Pay that Much in Shipping?

Even after making your package as small as possible, and comparison shopping for each of your packaging elements, you may still have a hefty shipping cost for a refrigerated product, and even more so for a frozen product. Before concluding that no one will pay that high of a shipping cost, consider these final e-food tips:

- Estimate what percentage of orders you expect to receive in your local region (where you can ship Ground) and what percentage of orders will require Air Mail.

Perhaps it’s okay to make less money on orders going further away, if you make more money on orders shipping closer to home? You can always adjust your shipping prices in the future after analyzing where your orders are actually coming from. - Include some of the shipping cost in the product price to allow you to set your shipping prices lower than your costs, while still covering your actual costs. For example, if you would normally charge $10 for your product, charge $12 instead. When a customer orders 4 of the items in one box, you’ll be generated $8 (4 x $2) in revenue to help cover some shipping cost.

- Remember that if you have a unique and delicious product that consumers want they might be more willing to pay high shipping costs than you think!

Need more information to help you develop your cold shipping system?

We’ve put together a comprehensive Cold Shipping Guide and Workbook for both refrigerated and frozen foods to help you out.

*This guide reflects the marketing expertise originally developed by Taste Profit Marketing, now Good Roots.